A Comprehensive Guide to Sand Making Plants and Machines

How does a sand plant produce sand?

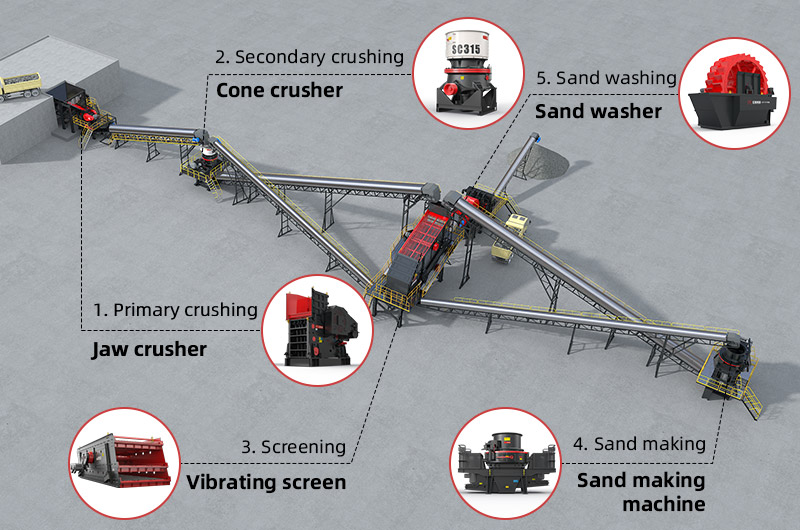

crushing (primary and secondary), fine crushing and sand making, screening, and sand washing. Each stage is interconnected to ensure efficient production and high-quality output.

1. Crushing (Primary and Secondary)

2. Fine crushing and sand making

3. Screening

4. Sand washing

-

Coarse sand: 0.5 mm每1 mm

- Medium sand: 0.25 mm每0.5 mm

- Fine sand: 0.125 mm每0.25 mm (125 米m每250 米m)

- Extra fine sand: 0.0625 mm每0.125 mm (62.5 米m每125 米m)

FTM Machinery customized sand making plant solutions

1. Kenya 180-230 tph pebble sand making plant

-

Project type: Hard rock pebble sand making

- Production capacity: 180每230 t/h

- Feed size: 300 mm每500 mm

- Output sizes: 0 mm每5 mm, 5 mm每20 mm, and 20 mm每40 mm

high automation and low operating costs.

a short return on investment, allowing clients to quickly recoup costs and continue to profit.

Main equipment configuration:

Sand production process:

-

1Vibrating feeding: The GZD-1100℅3600 vibrating feeder evenly delivers 300 mm每500 mm pebbles to the HD86(69) jaw crusher.

- 2Primary crushing: The jaw crusher reduces the size of the pebbles to below 150 mm.

- 3Secondary crushing: The crushed material is sent to the SC315 cone crusher for further reduction to 30 mm.

- 4Sand processing: The processed material is then refined by the HVI0922 sand maker to produce uniformly sized manufactured sand.

- 5Screening and classification: The 2YK2160 and 3YK2160 vibrating screens classify the manufactured sand into three specifications.

- 6Sand washing: The 3220 wheel sand washer cleans the manufactured sand, removing impurities to enhance the cleanliness and quality of the final product.

2. Nigeria 800tph limestone sand making plant

-

Project type: Soft rock limestone sand making

- Production capacity: 800 t/h

- Feed size: 200 mm每900 mm

- Output sizes: 0 mm每5 mm, 5 mm每10 mm, 10 mm每15 mm, 15 mm每25 mm

producing cubical sand and gravel with a low content of flaky particles.

Equipment configuration:

What equipment does a sand making plant need?

Main equipment list for sand making plant:

-

Crusher

- Crusher

- Crusher

- Crusher

- Crusher

- Vibrating feeder

- Vibrating screen

- Belt conveyor

1. Crushing equipment Crusher

-

Primary crushing: The jaw crusher is mainly used for primary crushing, breaking large hard materials like granite and river pebbles into medium-sized stones.

- Secondary crushing: The cone crusher or impact crusher is responsible for secondary crushing, further reducing the size of the stones to approximately 30 mm. The cone crusher is suitable for hard rocks, while the impact crusher is better for soft stones.

2. Sand making equipment Crusher

Large sand making machines for sale

HVI sand making machine, VSI sand making machine, and mobile sand making machine.

-

Applicable materials: Soft, medium-hard, and hard ores with a hardness of up to 320 MPa.

- Maximum feed size: Hard materials < 50 mm, soft materials < 55 mm

- Production capacity: Sand production capacity of 90每585 t/h; shaping sand capacity of 50每498 t/h.

it is more affordable and suitable for customers with limited budget. Under similar conditions, its production capacity exceeds that of the HVI sand maker by 10%, making it more widely used in various sand making plants.

-

Applicable materials: Medium-hard and hard materials.

- Maximum feed size: Hard materials < 45 mm, soft materials < 50 mm

- Production capacity: Center feed of 40每365 t/h; combined center and side feed of 80每650 t/h.

save a lot of costs associated with infrastructure, labor, and material transportation. It is an ideal choice for clients needing mobile operations or multi-site projects.

-

Applicable scenarios: Sand and gravel production, mining operations, and construction waste processing.

- Feed size: < 60 mm

- Production capacity: Center feed of 40每365 t/h; combined center and side feed of 80每650 t/h.

Small sand making machines for sale

roller crushers, fine crushers, small hammer crushers, and compound crushers, making them ideal choices for startups and users on a budget.

small, simple in structure, and low in price. It is widely used in small sand making projects, meeting daily sand production needs and helping users achieve stable output with low investment.

-

Suitable materials: Medium-hard, damp materials for crushing and sand making.

- Feed size: ≒ 30 mm

- Output size: 2 mm每10 mm

- Production capacity: 3每110 t/h

-

Suitable materials: Brittle materials with hardness below 9 for fine crushing.

- Output size: 1 mm每8 mm

- Production capacity: 5每260 t/h

How to choose the right sand making machine?

-

High capacity needs: Choose HVI sand making machines or VSI sand making machines for efficient production.

- Low capacity and budget: Roller crushers and fine crushers are ideal choices with low investment and quick returns.

- Large feed size: Small hammer crushers or compound crushers are suitable for handling larger materials.

- Multiple site mobility: Mobile sand making machines are flexible and suitable for various construction sites.

3. Sand washing equipment Crusher

small to medium sand plants.

Features:

-

Simple structure, easy maintenance, and high water utilization.

- Low water consumption, strong processing capacity, and clean output.

- Minimal sand loss, making it suitable for projects with less strict sand quality requirements, and it takes up relatively little space.

large sand production lines.

Features:

-

Spiral design allows for a large processing capacity and excellent cleaning results.

- It has a grading function to control sand particle size, improving the quality of the sand.

- Although it has higher sand loss, it provides a more thorough cleaning, resulting in better product quality, but it takes up more space.