Dressing Ways for 3 Kinds of Iron Ore Make You Profitable

2025/2/14 14:53:58 Other22025

Iron ore beneficiation ways, according to different kinds and natures of iron ore, can be divided into several processes. Among these ways, there are magnetic iron ore beneficiation, weakly magnetic iron ore beneficiation, and commensal iron ore beneficiation.

Iron ore beneficiation process

The main steps include crushing, screening, grinding, classification, separation (Crusher, flotation separation, and magnetic separation), water removing (concentration, filtration, and drying).

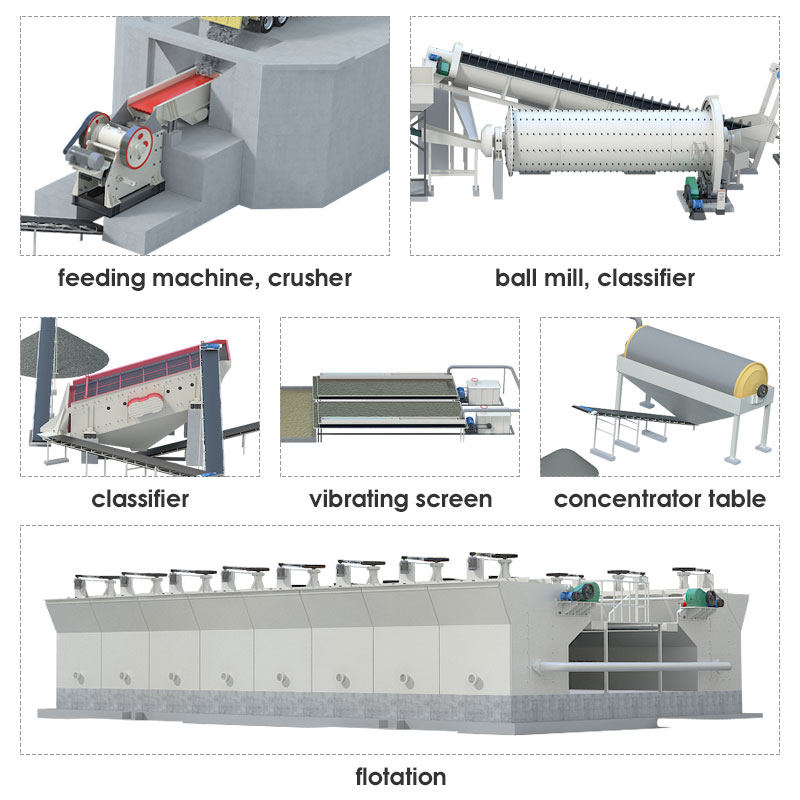

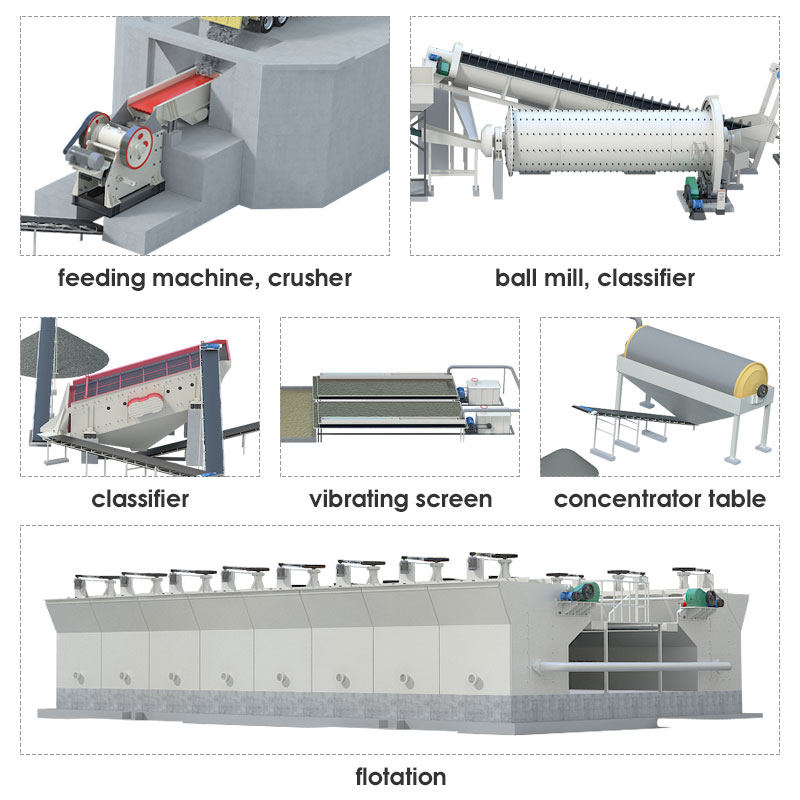

The related dressing machines are feeding machine, crusher, ball mill, classifier, vibrating screen, concentrator table, Crusher, agitating tank, flotation, and other machines.

Different iron ores should be dressed in different ways. According to the characteristics of different iron ores, the optimum dressing method can be used to achieve the best effect.

The following is a summary of the most powerful iron ore processing technologies, hoping you can get help:

Magnetic iron ore

Single magnetic ore

Single magnetic ore is mainly embedded in fine grains. Gangue minerals are mainly silicate minerals such as quartz and hornblende, some of which contain more iron silicate.

To dress this kind of iron ore, the low-intensity magnetic separation method is usually adopted. To further obtain high-grade concentrate, the magnetic concentrate is treated by reverse flotation or high-frequency screen.

For large and medium-sized magnetic separation plants, when the grinding particle size is larger than 0.2 mm, a single-stage grinding magnetic separation is often used. When less than 0.2 mm, a two-stage grinding magnetic separation is used.

If the qualified tailings can be separated by coarse grinding, the stage grinding magnetic separation can be adopted in the further process.

In areas lacking water, dry grinding and magnetic separation are used. When the rich magnetic ore or poor magnet ore is depleted, gangue minerals contained are removed first. For the rich magnetic iron ore, it can be processed into blocked rich iron ore, and for the lean iron ore, the concentrates can be obtained after grinding.

To obtain high-grade concentrate, magnetite concentrate can be treated by reverse flotation or high-frequency screen. To improve the recovery rate, tailings reprocessing can be considered for further recovery.

Polymetallic and magnetic iron ore

The polymetallic and magnetic iron ore is mainly sulfur magnetite and a few phosphorous magnetite.

The magnetite in the ore is embedded with medium to fine grain. Gangue has silicate or carbonate minerals, often accompanied by pyrite, cobalt pyrite or chalcopyrite, and apatite.

Generally, low-intensity magnetic separation and flotation are combined to separate the iron minerals from ores. In principle, the process can be divided into two types: low-intensity magnetic separation followed by flotation and flotation followed by low-intensity magnetic separation.

The different processes have different interlocked magnetite and sulfide.

In the process of low-intensity magnetic separation followed by flotation, the interlocked minerals mainly enter the iron concentrate. While flotation followed by low-intensity magnetic separation, the interlocked minerals mainly enter the sulfide concentrate.

Therefore, under the same grinding grain size, the iron concentrate with lower sulfide content, and the sulfide concentrate with a higher recovery rate can be obtained by flotation followed by low-intensity magnetic separation process.

Weakly magnetic iron ore

Single weakly magnetic iron ore

The single weakly magnetic iron ore consists of hematite, siderite, limonite, and hematite in sedimentary and metamorphic, sedimentary, hydrothermal, and weathered deposits.

Different kinds of iron ores

Due to the variety of minerals and grain sizes, there are also many single weakly magnetic iron ore dressing methods.

The commonly used method is magnetization calcination magnetic separation or a combined process with one of gravity separation, flotation, and strong magnetic separation, and can also be combined with gravity separation, flotation, and strong magnetic separation separately.

Calcination magnetic separation

The calcination magnetic separation is one of the effective methods of weakly magnetic iron ore separation from the sizes between fine and tiny particles (smaller than 0.02 mm).

When the ore contains rich minerals and is difficult to separate out, the magnetization calcination magnetic separation can be preferred to use.

When the minerals in the ore are complex and it is difficult to get good indexes by other methods, the magnetization calcination magnetic separation method should be used.

For blocked ores with a size of 20 to 75 mm, it can be processed in shaft furnace for reduction calcination.

Re-separation, flotation, strong magnetic separation, or a combined dressing process

Flotation is one of the common methods for separating fine to tiny particles of weakly magnetic iron ore.

In general, there are two frequently-used processes: positive flotation and reverse flotation.

Iron ore beneficiation ways

The former is suitable for quartzite hematite which does not contain the easily-floating gangue, while the latter is suitable for the one which contains easily-floating gangue ore.

The weakly magnetic iron ore with a size of 2 to 20 mm is mainly dressed by gravity separation and strong magnetic separation.

The weakly magnetic iron ore with size more than 20 mm is mainly dressed by dense medium separation and jigging separation.

Currently, a combined process by strong magnetic and gravity separation is often used because of the low recovery rate and capacity of fine iron ores in gravity separation.

During this process, strong magnetic separation is firstly used to separate a large number of tailings, and gravity is secondly used to process strong magnetic concentrates to further improve the grade.

Polymetallic and weakly magnetic iron ore

Polymetallic and weakly magnetic iron ore is mainly hematite or siderite containing phosphorus or sulfide compounds in hydrothermal and sedimentary type.

This kind of ore is often embedded with particles, and closely commensal with gangue in an olite texture, which is difficult to dissociate.

Therefore, iron minerals in this kind of ores are generally recovered by gravity separation, flotation, strong magnetic separation, or combined processes, and phosphorus or sulfide are recovered by flotation.

If it is a rich ore or a self-melting ore, the gangue can be removed through dense medium separation, jigging, or dry strong magnetic separation, and the bulk iron ore can be obtained.

-

If it is rich olite ore, the method of calcination magnetic separation can be used.

-

While for the poor olite ore, the grade of concentrate is hard to reach more than 50% even if it is processed by calcination magnetic separation. Therefore, it can be mixed with other high-grade concentrates for further beneficiation.

-

Hydrothermal quartzite hematite and limonite are often inlaid in-uniformly and are separated by a combined process consisting of gravity separation, strong magnetic separation, and flotation.

Commensal iron ore

Single commensal iron ore

The single commensal iron ore is mainly combined with hematite and magnetite or magnetite and siderite. In this kind of iron ore, magnetite, hematite, and siderite are mostly embedded finely.

Commensal iron ore

There are two common dressing methods for this kind of iron ore:

Combining low-intensity magnetic separation with gravity separation, flotation, and strong magnetic separation

When the low-intensity magnetic separation combines with gravity magnetic separation, flotation, and strong magnetic separation, magnetite is recovered by low-intensity magnetic separation, and weakly magnetic iron ore is recovered by gravity separation, flotation or strong magnetic separation.

Calcination magnetic separation method or a combined process with other methods

When the combined process of calcination magnetic separation method or a combined process with other methods is adopted, the concentrates recovered by calcination magnetic separation are further selected by flotation, gravity separation, or magnetic separation to improve the grade of concentrates.

Polymetallic commensal iron ore

The polymetallic commensal iron ore is mainly formed of magnetite and hematite or siderite, which are embedded in medium to fine grains. Its gangue rocks include silicate and carbonate minerals or jadeite, etc. And the commensal components are apatite, pyrite, chalcopyrite, and rare earth minerals.

Polymetallic commensal iron ore

The beneficiation method of this kind of ore is the most complex among all kinds of iron ores. Generally, the combined process of weakly magnetic separation and other methods is adopted.

That is, recovering magnetite by low-intensity magnetic separation, recovering weakly magnetic iron ore by gravity separation, flotation or strong magnetic separation, and recovering commensal components by flotation.

For iron ore containing rare earth minerals, when the iron ore contains a large amount of hematite, the process of reduction calcination magnetic separation and flotation can also be used to reduce the iron ore, and the rare earth minerals can be flotation after reduction calcination.

The above are useful and powerful ore dressing methods. For the separation of iron ore, the author suggests that it is better to customize the appropriate dressing methods of minerals instead of applying the method of mineral processing arbitrarily.