Things You Need to Know about Granite

What is granite?

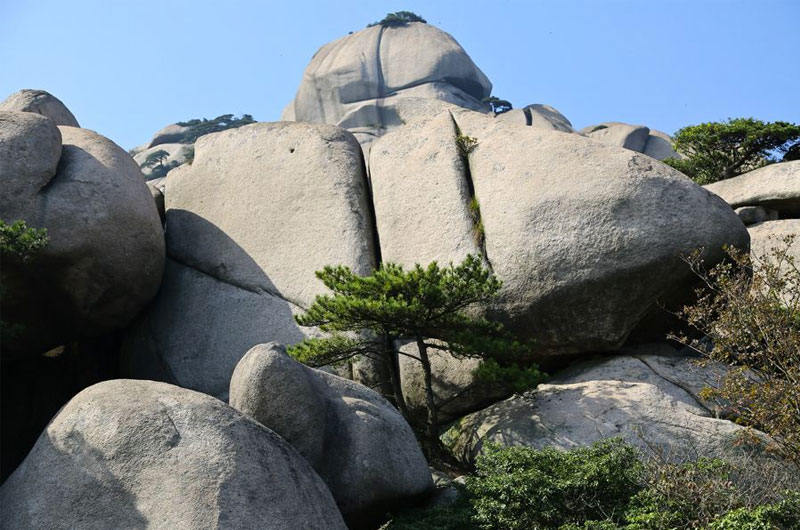

Statistics show that granite is one of the oldest rocks on the earth with a history of more than 300 million years. Granite is the most widespread igneous rock and is the main material for the Tianzhushan Global Geopark, Menkaures Pyramid, etc.

Granite stones

Granite is formed by the cooling of magma, so it is called intrusive rock. The forming depth is usually 5 to 30 kilometers below the earths surface, so it is also called deep-seated rock.

What color is granite?

Granite countertop in different colors

The Crusher depends on its components, usually presenting red, pink, gray, white, black, and other dark colors. If granite contains much potash feldspar, it will be pink; if it contains much quartz, it may appear white.

-

Quartz-typically milky white

- Feldspar- typically off-white

- Potash feldspar- typically pink

- Biotite- typically black or dark brown

- Muscovite- typically gold or yellow

- Amphibole - typically black or dark green

How is granite formed?

Granite is formed by the cooling of magma. There is a deep layer of molten rock in the depths of the earth and beyond the mantle layer.

Molten rock is formed when the natural radioactive elements in the ground decompose and decay. The reaction of the decaying matter releases a lot of heat, melting the surrounding rocks.

As geological matters occur (such as the plate movements), molten rock is pushed to the surface of the earth. As the rock approaches the ground, it will cool, forming an internal igneous rock.

Granite is one of these igneous rocks, which can be a mixture of mainly quartz and feldspar.

What materials are in granite?

Granite is divided into two major series: the calc-alkaline series containing plagioclase and alkaline feldspar, and the alkaline series containing alkaline feldspar and alkaline dark minerals. The former is collectively called granite, and the latter is called alkaline granite.

The common granites are gray and red, with the main minerals of quartz, potash feldspar, titanite, acid plagioclase, the minor minerals of biotite, hornblende, and pyroxene, and the accessory substances of phosphorite, zircon, sphene, magnetite.

The main feature of granite is that it contains more alkaline feldspar (mainly potash feldspar) than plagioclase. Alkaline feldspar generally accounts for 60% to 90% of the total feldspar, and the quartz contained is mostly about 30%. The dark mineral content is about 5% to 10%.

The nature of granite

Granite has the futures of pyknotic structure, high compressive strength, low water absorption, stable chemical performance, strong durability but poor fire resistance.

Generally, granite has a granular structure or a porphyritic structure with fine, medium and coarse grains. Its particles are uniform and dense, with small gaps (the porosity is generally 0.3% to 0.7%), and the water absorption rate is low (generally 0.15% to 0.46%).

In addition, granite has a high hardness of 6 according to the Mohs hardness. The density of granite is at the range of 2.63 g/cm3 to 2.75 g/cm3. Meanwhile, the compressive strength of granite is about 100MPa to 300 MPa.

The fine granite can reach up to 300 MPa of its compressive strength and 10 MPa to 30 MPa of bending strength.

How is granite extracted?

How to mine granite rocks

The basic mining process of granite includes mountain separation, rock division, and product shaping.

1. Mountain separation process

The main separation ways are splitting, drill blasting and flames cutting.

2. Rock cutting process

Turn over the chipped stones separated from the rock mass by a capstone machine, and then cut the strips into the required blocks according to the crack rules and block specifications.

3. Shaping process

The divided blocks need to be shaped if they do not meet the requirements. It commonly uses a hammer or shaping machine to remove the excess part of the blocks to make them flat and neat.

How to process granite

The basic processing methods of granite include sawing, grinding, polishing, cutting, chiseling, singeing, and auxiliary processing.

1. Sawing

This process is a rough machining process, which has a significant impact on the utilization rate, quality of granite boards, and the economic benefits of the enterprise.

The commonly used equipment for sawing and processing includes a large automatic sanding saw for granite; a multi-blade bidirectional cutter bar, a multi-blade granite cutting machine, and a circular sawing machine.

2. Grinding and polishing

This part aims to further process the sawn rough board to make its thickness, flatness, and gloss meet the requirements.

First, roughly grind the granite materials;

Second, finely grind the semi-finished granite product;

Third, polish the granite countertop to achieve the best decorative effect.